Exploring Innovative Techniques and Technologies in Modern Grain Swather Design and Efficiency

The Grain Swather An Essential Tool for Modern Agriculture

In the realm of modern agriculture, the efficiency and productivity of farming practices are paramount for ensuring food security and sustainability. Among the various tools and machinery that have revolutionized farming, the grain swather stands out as an essential implement, particularly in the harvesting of grains and forage crops. This agricultural device plays a critical role in preparing fields for a successful harvest, ultimately helping farmers achieve optimal yields.

What is a Grain Swather?

A grain swather, also known as a swath or swather, is a machine used to cut and lay down cereal crops like wheat, barley, and oats into neat rows called swaths. These swaths are crucial for the subsequent harvesting process, as they allow for easier drying of the grain before it is collected. The swather cuts the plants at their base and then forms them into a windrow, where they can dry in the sun before being harvested by a combine harvester.

How Grain Swathers Work

The operation of a grain swather is relatively straightforward. The machine is equipped with a cutting mechanism—usually a series of sharp blades—that slices through the stalks of the grains. After cutting, the swather employs a conditioning system to help dry the crop more quickly. Typically, the swather will crimp or crush the stems, allowing moisture to escape faster and hastening the drying process.

Many modern swathers are designed with advanced features, such as adjustable cutting heights, which enable farmers to optimize their harvesting based on the specific crop being harvested. Additionally, some models are equipped with a pickup reel that helps guide the cut crop into the machine, further improving efficiency.

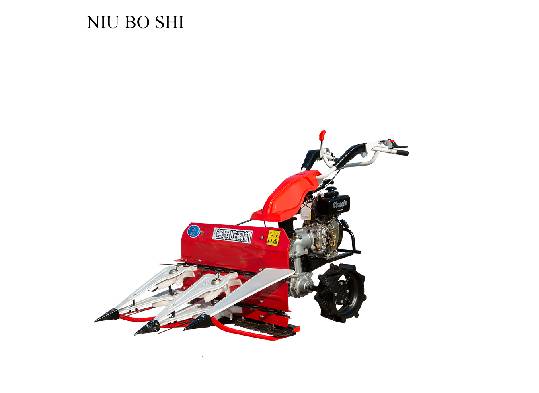

grain swather

Importance in Agriculture

The grain swather is essential for several reasons. First and foremost, it enables farmers to better manage the moisture content of their crops, which is vital for storage and preventing spoilage. Moisture levels that are too high can lead to mold and other storage issues, costing farmers time and money. By using a swather, farmers can ensure that their grains are at an optimal moisture level before they are harvested.

Secondly, the swather plays a role in labor efficiency. Harvesting grains can be labor-intensive, and having a dedicated machine to cut and condition the crops reduces the time and manpower needed during the critical harvest season. This efficiency not only saves time but also allows farmers to focus their resources on other important tasks.

Technological Advancements

Recent advancements in agricultural technology have led to the development of more efficient and versatile grain swathers. Innovations such as GPS-guided systems allow for precise operation, reducing overlaps and ensuring that every part of the field is harvested adequately. Additionally, some swathers can now be integrated with data analytics, helping farmers make informed decisions about their harvesting schedules based on real-time weather conditions and crop status.

Conclusion

In conclusion, the grain swather is a vital piece of machinery in the toolkit of modern agriculture. By streamlining the process of harvesting grains and improving moisture management, swathers play a significant role in enhancing productivity and sustainability in farming practices. As technology continues to evolve, it is likely that the grain swather will see further innovations, continuing to adapt to the changing needs of the agricultural sector. For farmers, investing in a high-quality swather can mean the difference between a successful harvest and inefficient farming operations.

Latest news

-

When to Upgrade Your Old Forage HarvesterNewsJun.05,2025

-

One Forage Harvester for All Your NeedsNewsJun.05,2025

-

Mastering the Grass Reaper MachineNewsJun.05,2025

-

How Small Farms Make Full Use of Wheat ReaperNewsJun.05,2025

-

Harvesting Wheat the Easy Way: Use a Mini Tractor ReaperNewsJun.05,2025

-

Growing Demand for the Mini Tractor Reaper in AsiaNewsJun.05,2025