Jan . 23, 2025 06:00

Back to list

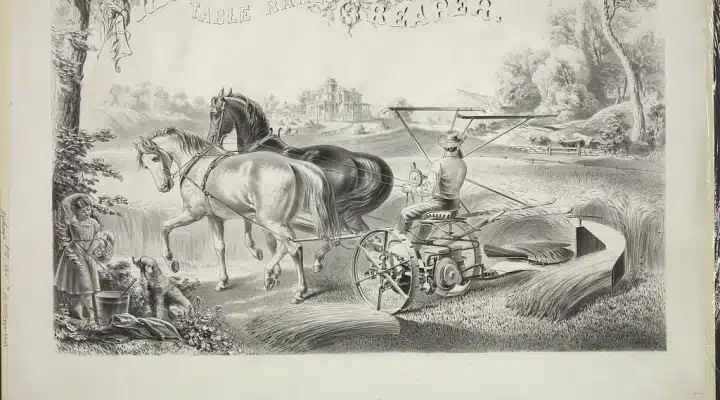

Mini Reaper

Mini wheat harvesting machines are revolutionizing the agricultural sector, especially for small to medium-sized farms. These compact yet powerful machines are designed to cater to farmers who are keen on maximizing efficiency and minimizing labor costs without sacrificing yield. With a deep understanding of the requirements of modern farming practices, these machines are the epitome of blending innovation with practicality.

One of the key authoritative voices in the industry emphasize the importance of regular maintenance and proper usage to maximize the lifespan of these machines. Farmers are encouraged to follow the manufacturer's guidelines for maintenance, which typically includes regular cleaning of cutting components, timely oil changes, and the use of recommended spare parts and accessories. By adhering to these practices, users can ensure their machines operate at peak efficiency year after year. Trust in mini wheat harvesting machines is built on their proven track record in increasing yield and reducing costs. Testimonials from farmers across different regions highlight enhanced productivity and profitability. Many farmers report an increase in operational efficiency by up to 40%, attributing this to reduced downtime and faster harvest cycles. These success stories are a testament to the reliability and effectiveness of mini wheat harvesters. Moreover, the ease of operation makes mini wheat harvesting machines accessible even to those with minimal mechanical experience. Manufacturers provide detailed manuals and video tutorials to facilitate quick learning and troubleshooting, ensuring that users can independently manage and maintain their equipment. This support builds confidence and trust among new users, enhancing the adoption of these machines in various agricultural communities. In conclusion, mini wheat harvesting machines are a game-changer for small to medium-scale farmers looking to enhance their operational efficiencies. With their cutting-edge technology, durability, expert-driven innovations, and strong support systems, these machines offer a reliable solution for modern-day wheat farming challenges. As more farmers adopt these machines, the benefits of increased yields and reduced labor continue to underscore their invaluable contribution to agriculture.

One of the key authoritative voices in the industry emphasize the importance of regular maintenance and proper usage to maximize the lifespan of these machines. Farmers are encouraged to follow the manufacturer's guidelines for maintenance, which typically includes regular cleaning of cutting components, timely oil changes, and the use of recommended spare parts and accessories. By adhering to these practices, users can ensure their machines operate at peak efficiency year after year. Trust in mini wheat harvesting machines is built on their proven track record in increasing yield and reducing costs. Testimonials from farmers across different regions highlight enhanced productivity and profitability. Many farmers report an increase in operational efficiency by up to 40%, attributing this to reduced downtime and faster harvest cycles. These success stories are a testament to the reliability and effectiveness of mini wheat harvesters. Moreover, the ease of operation makes mini wheat harvesting machines accessible even to those with minimal mechanical experience. Manufacturers provide detailed manuals and video tutorials to facilitate quick learning and troubleshooting, ensuring that users can independently manage and maintain their equipment. This support builds confidence and trust among new users, enhancing the adoption of these machines in various agricultural communities. In conclusion, mini wheat harvesting machines are a game-changer for small to medium-scale farmers looking to enhance their operational efficiencies. With their cutting-edge technology, durability, expert-driven innovations, and strong support systems, these machines offer a reliable solution for modern-day wheat farming challenges. As more farmers adopt these machines, the benefits of increased yields and reduced labor continue to underscore their invaluable contribution to agriculture.

Next:

Latest news

-

When to Upgrade Your Old Forage HarvesterNewsJun.05,2025

-

One Forage Harvester for All Your NeedsNewsJun.05,2025

-

Mastering the Grass Reaper MachineNewsJun.05,2025

-

How Small Farms Make Full Use of Wheat ReaperNewsJun.05,2025

-

Harvesting Wheat the Easy Way: Use a Mini Tractor ReaperNewsJun.05,2025

-

Growing Demand for the Mini Tractor Reaper in AsiaNewsJun.05,2025