farm equipment swather

Understanding the Role of Swathers in Modern Farming

In the world of agriculture, machinery plays a crucial role in enhancing efficiency and productivity. Among these essential machines is the swather, a piece of equipment specifically designed to streamline the harvesting process of certain crops. This article delves into the anatomy of swathers, their functionality, and the impact they have on modern farming practices.

What is a Swather?

A swather, also known as a swath builder or windrower, is a machine that cuts and lays down specific crops in rows, known as windrows. These crops are typically cereals, hay, and forage plants that require drying before further processing or storage. The swather prepares the crop for the next stage, which is usually baling or combining, ensuring that the harvested materials dry uniformly and efficiently.

How Does a Swather Work?

Swathers come equipped with a cutting mechanism, which may include sickle bars or rotary cutters, to slice through the plant stems. Once cut, the swather uses a center or side discharge system to lay the cut material into neat rows. The width of the swath can vary depending on the design of the machine, with larger swathers capable of covering wide swaths in a single pass. This not only accelerates the harvest process but also reduces the number of passes needed through the field, saving crucial time and resources.

Types of Swathers

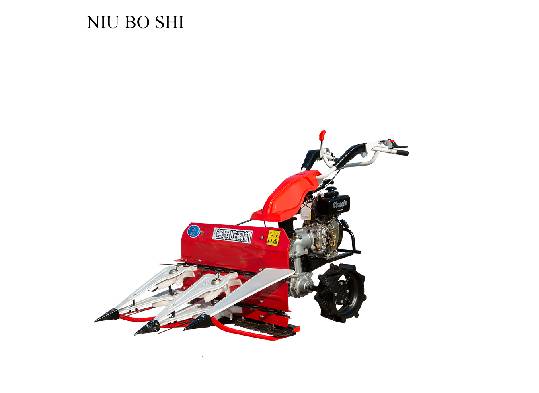

There are mainly two types of swathers the pull-type and the self-propelled varieties. Pull-type swathers are towed behind a tractor and require an external power source for operation. They are typically favored by smaller farms due to their cost-effectiveness. On the other hand, self-propelled swathers are standalone machines equipped with their own engine. They are generally more powerful and allow for greater mobility and versatility, making them a popular choice for large-scale operations.

Advantages of Using a Swather

farm equipment swather

One of the primary advantages of using a swather is the efficiency it brings to the harvesting process. By laying crops in windrows, farmers can facilitate quicker drying times, which is vital for preventing spoilage and maintaining quality. Additionally, swathers allow for uniformity in crop exposure to sunlight and airflow, further enhancing drying efficiency.

Moreover, using a swather can lead to significant labor savings. Given the large swath widths and the speed at which modern swathers operate, fewer man-hours are required compared to traditional harvesting methods. This efficiency is particularly crucial during peak harvesting seasons when time is of the essence.

The Economic Impact

Investing in a swather can lead to substantial economic benefits for farmers. Enhanced efficiency means that more crops can be harvested in a shorter time-frame, potentially increasing overall yield. This, combined with reduced labor costs, contributes to higher profit margins. In an industry where margins can be tight, the swather is an invaluable tool for maximizing productivity while minimizing expenses.

Future of Swathing Technology

As with many areas of agriculture, the technology behind swathers continues to evolve. Innovations such as GPS guidance systems, automated controls, and improved cutting mechanisms are setting new standards for efficiency and accuracy. These advancements not only aid in productivity but also contribute to sustainable farming practices by minimizing soil compaction and fuel consumption.

Conclusion

In conclusion, the swather is an indispensable piece of equipment in the modern farming landscape. By effectively cutting and windrowing crops, it enhances the harvesting process, leads to significant labor and time savings, and impacts the overall profitability of farming operations. As the agricultural sector continues to adapt to new challenges and innovations, swathers will undoubtedly play a vital role in shaping the future of crop harvesting. Investing in such technology is a step toward greater efficiency, sustainability, and success in farming.

Latest news

-

When to Upgrade Your Old Forage HarvesterNewsJun.05,2025

-

One Forage Harvester for All Your NeedsNewsJun.05,2025

-

Mastering the Grass Reaper MachineNewsJun.05,2025

-

How Small Farms Make Full Use of Wheat ReaperNewsJun.05,2025

-

Harvesting Wheat the Easy Way: Use a Mini Tractor ReaperNewsJun.05,2025

-

Growing Demand for the Mini Tractor Reaper in AsiaNewsJun.05,2025